Metal plays a vital role in modern architecture, infrastructure, and industrial applications. Its strength, versatility, and aesthetic appeal make it a preferred material across sectors. However, constant exposure to sunlight, rain, humidity, pollution, and temperature fluctuations can compromise performance over time. This is why weather-resistant metal finishes have become essential in extending durability, preserving appearance, and reducing long-term maintenance. Solutions such as anodised aluminium sections demonstrate how engineered finishes can protect metal surfaces while supporting demanding performance expectations.

Understanding the Impact of Weather on Metal Surfaces

Before examining specific challenges, it is important to understand how environmental exposure affects metal over time. Weather-related stress does not occur all at once; instead, it gradually weakens surfaces through repeated exposure to natural elements. The following factors play a key role in this process.

Environmental Stress Factors

Outdoor metal components face continuous environmental pressure. Ultraviolet radiation can break down surface layers, moisture accelerates corrosion, and pollutants trigger chemical reactions that weaken protective coatings. In coastal and industrial regions, salt and chemical exposure further intensify deterioration.

Consequences of Inadequate Protection

Without proper finishing systems, metal surfaces may fade, corrode, or crack prematurely. This leads to structural vulnerabilities, increased maintenance costs, and shortened service life, all of which affect long-term project value.

What Makes a Metal Finish Weather-Resistant

Weather resistance is not achieved through a single protective layer. Instead, it is the result of carefully engineered systems working together. From chemical composition to surface preparation, each component contributes to long-term durability and performance.

Role of Resin Technology

The foundation of any durable metal finish lies in its resin system. Resin chemistry determines resistance to corrosion, chalking, UV exposure, and physical stress. Each resin type is engineered for specific performance requirements rather than generic applications.

Importance of Pigment Engineering

Pigments do more than add color. They control fading behavior, reflectivity, and long-term brightness. Every color formulation reacts differently to environmental conditions, which is why extensive testing is required before finishes are approved for real-world use.

Pretreatment and Substrate Preparation

Before any finish is applied, the metal surface undergoes pretreatment. This process cleans, conditions, and chemically prepares the substrate, ensuring strong adhesion and enhanced corrosion resistance beneath the visible surface.

Balancing Durability with Visual Appeal

While protection is a primary requirement, modern construction also demands a strong visual appeal. Today’s metal finishes must deliver both performance and aesthetics, ensuring structures remain visually appealing long after installation.

Long-Term Aesthetics Matter

While durability is critical, appearance is equally important in residential and commercial projects. Modern weather-resistant finishes allow designers to achieve bold colors, subtle matte effects, and metallic textures without sacrificing performance.

Advances in Finish Technology

Recent innovations have made it possible to create ultra-low-gloss matte finishes with strong UV resistance. Metallic and high-sheen effects have also entered mainstream architectural design, delivering both visual depth and long-term stability.

Different Coating Systems and Their Performance Roles

Not all coating systems are designed to perform the same way under every condition. Understanding how different systems respond to environmental stress helps designers and builders select the most appropriate solution for each application.

Matching Coatings to Environments

Not all finishes perform the same in every climate. Some are designed for flexibility and forming, while others prioritize UV stability and color retention. Abrasion resistance is also critical during transport and installation.

Thin Film, High Performance

Despite being only microns thick, modern finishes are engineered to deliver decades of protection. Advances in chemistry allow thinner film builds to perform at levels once achieved only by thicker, material-heavy coatings.

Aluminium and Long-Term Weather Resistance

Aluminium has become a preferred material across industries due to its natural properties. When combined with advanced finishing techniques, it offers exceptional resistance to weather-related damage, making it suitable for long-term outdoor use.

Why Aluminium Is Widely Used

Aluminium naturally resists corrosion and offers excellent strength-to-weight performance. When combined with advanced surface treatments, it becomes even more durable for outdoor applications.

Enhanced Protection Through Surface Treatments

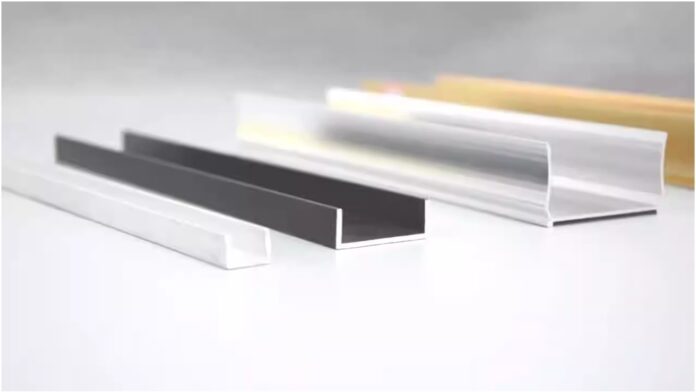

Midway through many architectural and infrastructure projects, designers rely on anodised aluminium sections for facades, windows, railings, and structural components. Anodising strengthens aluminium’s natural oxide layer, creating a finish that becomes part of the metal rather than sitting on top of it.

Sustainability Benefits of Weather-Resistant Finishes

Beyond durability and appearance, sustainability has become a key consideration in material selection. Weather-resistant finishes contribute to environmentally responsible construction by extending service life and reducing resource consumption.

Reduced Maintenance and Material Waste

Durable finishes extend service life, reducing the need for frequent replacements or repairs. This lowers material consumption over time and minimizes environmental impact.

Eco-Conscious Coating Innovations

Modern metal finishes increasingly use water-based systems, reduced solvent content, and recyclable materials. Thin film technologies also support sustainability goals by achieving high performance with minimal material use.

Energy Efficiency and Thermal Performance

Metal finishes also influence how buildings interact with heat and sunlight. Advances in coating technology now allow surfaces to play an active role in managing thermal performance and energy efficiency.

Reflective Pigment Technology

Certain finishes are engineered to reflect infrared radiation, helping control surface temperatures. Even darker colors can now offer improved solar reflectance, contributing to energy efficiency.

Aluminium’s Thermal Advantage

Aluminium naturally dissipates heat efficiently. When paired with reflective, weather-resistant finishes, it supports thermal comfort and reduces cooling demands in buildings.

Importance of Proper Specification and Application

Even the most advanced finish can underperform if it is not specified or applied correctly. Attention to detail during selection and installation ensures that weather-resistant systems deliver their intended benefits.

Factors Influencing Service Life

Performance depends on correct specification, including coating thickness, substrate choice, exposure conditions, and installation quality. A finish suitable for one environment may underperform in another.

Informed Material Selection

Professionals must consider climate, pollution levels, mechanical stress, and project requirements to ensure finishes perform as intended over the long term.

Future Trends in Weather-Resistant Metal Finishes

As environmental demands and design expectations continue to evolve, metal finishing technologies are advancing rapidly. Ongoing research is focused on improving performance while meeting sustainability and aesthetic goals.

Innovation Focus Areas

Research continues to push boundaries in durability, sustainability, and flexibility. Future developments include adaptive thermal coatings, enhanced matte finishes, and even thinner film systems with extended lifespans.

Meeting Evolving Design Demands

As architectural designs grow more complex, finishes must balance formability with protection, ensuring metal remains both functional and visually compelling.

Conclusion

Weather-resistant metal finishes play a critical role in protecting structures from environmental damage while preserving appearance and performance. Through advanced chemistry, precision engineering, and sustainable practices, these finishes ensure metal components withstand decades of exposure. Solutions such as anodised aluminium sections highlight how durability, efficiency, and design can coexist in modern construction.

Within this broader context, JM Aluminium is often associated with applications where consistency, material reliability, and long-term performance are essential. Their experience with aluminium solutions reflects a practical understanding of how weather-resistant finishes support durability, sustainability, and architectural integrity across diverse environments.